〜しばしも休まず 槌うつ響き 飛び散る火花よ 走る湯玉 ふいごの風さえ 息をもつがず

仕事に精出す 村の鍛冶屋

あるじは名高い 働き者よ 早起き早寝の やまい知らず 永年鍛えた 自慢の腕で

打ち出す鋤鍬(すき くわ)心こもる〜「童謡・村の鍛冶屋」

日本の「ものづくり」産業史のなかでこのような童謡でまで語り継がれている職種は希少だろう。メロディのテンポの良さ、歯切れのいい歌詞。小学校の時にこの歌を歌いながら、強く心を鼓舞された記憶がある。

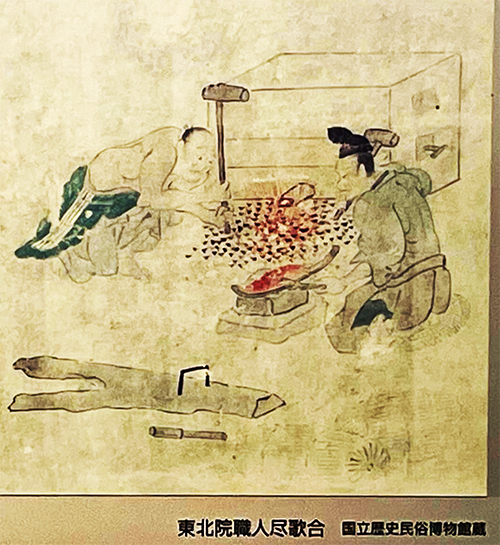

大好きだったのだろう。日本のこどもたちにいかにも「ものを作っている」という職人の誇りを現実の労働で示し続けた意味で、強くリスペクトさせられたように思う。写真でも、主力火力に対して注連縄で結界を表現して、心正しく真剣に一期一会のものづくりに邁進する姿が立ち上ってくる。

古代史のなかで白村江海戦など日本が朝鮮半島の権力闘争に深く関与していたのは、なによりも鉄の生産と確保が日本国家権力の大命題として存在し、その産業確保自体が中核的なテーマだっただろうことをあらわしている。日本において本格的に製鉄が開始されたのは、5世紀から6世紀にかけてとされる。

中国地方で「たたら製鉄」が始原したのは、いつの頃からなのか、そこで生産された原料鉄を使って、より消費地に近い地域で、それぞれの需要に対応した地域産業として「鍛冶屋」は成立したのでしょう。

基本的には農業土木の生産性を飛躍的に高めた存在として農業鉄器があり、同時に刀などの軍事用途が平行的に発展していったと推定される。今日のクルマ産業にまで至る日本の産業基盤だと強く思う。

この草戸千軒でも、周辺の農業地帯への農機の提供ということがまず第一の成立根拠だっただろう。中国地方の山地地域で生産された原料鉄は芦田川水系を使って河口域の草戸千軒に運ばれ、この「製鉄所」で加工・製品化されて周辺地域に普及し、さらに瀬戸内海交易を通じて堺などの大消費地にも伝播していったことだろう。

生産物毎に各地に特産地が形成され、和泉堺の庖丁、播磨三木の大工道具、越後三条・越前武生の鎌、近江甲賀・土佐山田の木挽鋸などがその代表格とされるようになっていった。交易はそういった産地間競争を刺激する最高の試練の場、公平な競争機会を提供したのだろう。日本の製造業は、こうした国内産業同士の激しい競争によって常に革新され発展してきたことだろう。

「あるじは名高い 働き者よ」というのは、日本社会がこういった競争を生産者に強いた表現の一種であるのかも知れない。日本の市場が歴史的に培ってきた生産者への創造力刺激パワー。

English version⬇

[The “town blacksmith,” a manufacturer who forges day and night – Kusado Senken 2023 Revisited-8

It continued to stimulate the spirit of “monozukuri” (manufacturing) in both rhythm and melody, the best of all the nursery rhyme songs. The core of the Japanese spirit. …

〜The sound of hammering, the echo of hammering, the sparks flying, the running balls of hot water, even the wind from the blowpipe, breathless…

The village blacksmith, hard at work

A master blacksmith, renowned for his hard work, early to rise, early to bed, never getting sick, his skill trained over many years

The plow and hoe he hammers out, with all his heart – “The Village Blacksmith,” a children’s song

In the history of Japan’s “monozukuri” (manufacturing) industry, it is rare to find an occupation that has been passed down through the generations in a children’s song like this one. The tempo of the melody and the crisp lyrics. I remember being strongly inspired while singing this song in elementary school.

I must have loved it. I think I was made to respect it strongly in the sense that it continued to demonstrate to Japanese children the pride of craftsmen who were “making things” through real labor. Even in the photo, the image of the craftsman using a shimenawa to express a boundary against the main fire power rises to the surface as he strives to make things right in his heart and earnestly, once in a lifetime.

In ancient history, Japan was deeply involved in the struggle for power on the Korean peninsula, including the Battle of Hakuchon River, indicating that above all, the production and securing of iron was a major mission of the Japanese state power and that securing the industry itself was a core theme. Iron manufacturing in Japan is said to have begun in earnest in the 5th and 6th centuries.

When did “tatara iron manufacturing” begin in the Chugoku region? Using the raw iron produced there, “blacksmithing” must have been established as a local industry in areas closer to consumption areas to meet the respective demands.

Basically, it is presumed that agricultural ironware existed as an entity that dramatically increased the productivity of agricultural engineering, and at the same time, military uses such as swords developed in parallel. I strongly believe that this is the industrial foundation of Japan that has led to today’s car industry.

The first and foremost reason for the establishment of Kusado-Senken would have been to provide agricultural machinery to the surrounding agricultural areas. The raw iron produced in the mountainous areas of the Chugoku region was transported to Kusado-Senken at the mouth of the river using the Ashida River system, processed and commercialized at this “ironworks”, and spread to the surrounding areas, and then to large consumption areas such as Sakai through trade on the Seto Inland Sea.

Each product formed its own specialty area, and the kitchen knives of Izumi Sakai, carpenters’ tools of Harima Miki, sickles of Echigo Sanjo and Echizen Takefu, and wood saws of Omi Koga and Tosa Yamada became representative of these areas. Trade probably provided the best testing ground and fair competitive opportunities to stimulate such competition between production centers. Japanese manufacturing industries have always innovated and developed through such fierce competition among domestic industries.

The phrase, “Aruji wa kamihaso hirusha” (“Aruji is a famous worker”) may be a kind of expression of the Japanese society that forced producers to compete in this way. The Japanese market has historically cultivated the power to stimulate creativity among producers.

Posted on 12月 20th, 2023 by 三木 奎吾

Filed under: 住宅マーケティング, 日本社会・文化研究

コメントを投稿

「※誹謗中傷や、悪意のある書き込み、営利目的などのコメントを防ぐために、投稿された全てのコメントは一時的に保留されますのでご了承ください。」

You must be logged in to post a comment.